Aluminium International Today News

-

Secondary aluminium producers: a new range of saws to open up new opportunities

Extruders, remelters and distributors of secondary aluminium often find it difficult to find band saws adapted to their needs. The machines available on the market are mostly designed for ferrous metals such as steel or inconel and require adaptations that are not always optimal to meet the needs of aluminium sawing.

Sermas provides the industry with a solution.

03 November 2021 -

Getting the competitive edge in manufacturing

The future of automation and mechanical engineering undoubtedly lies in the unstoppable digitisation of data. In today’s modern production process, it is becoming increasingly inefficient to use single-purpose equipment for individual processes, with its high costs and insufficient productivity.

Noel Sheppard and Paola Hopwood discuss how manufacturers can realise the benefits of edge computing through network automation.

03 November 2021 -

Levelling and splitting technology

E-mobility has already fundamentally changed the everyday working lives of many companies and employees in the automotive industry. Planning engineers and production managers as well as assembly workers are confronted with the challenges in levelling and slitting technology in their daily work.

28 October 2021 -

IAI models 1.5-degree decarbonisation scenario in a bid to drive greater emissions reductions

Investment in technology is a major step in tackling climate change across aluminium industry.

The International Aluminium Institute (IAI) has modelled a 1.5 Degree Scenario to guide its member’s efforts to meet global climate goals. The modelling is based on IEA’s Net-Zero by 2050 scenario, combined with the IAI’s material flow analysis and future demand scenarios.

27 October 2021 -

Mastering challenges in aluminium extrusion through the use of premium steels

Werner Hähnel discusses tool costs and tool life are decisive for the performance of an extrusion line.

The pure tool costs are always put in relation to the service life achieved. Furthermore, the use of premium tool steels increases the product quality because the premium grade has a higher strength and toughness. The use of premium tool steel is also more economical because fewer tools have to be changed and thus there is a higher availability of the extrusion press. In addition, premium tool steels enable the production of particularly critical profile geometries.

19 October 2021 -

AlumForum 2021 - a unique event for the Russian aluminium industry

The II International Forum “Aluminum in Architecture and Construction” was successfully held in Moscow on 21-23 September 2021.

11 October 2021 -

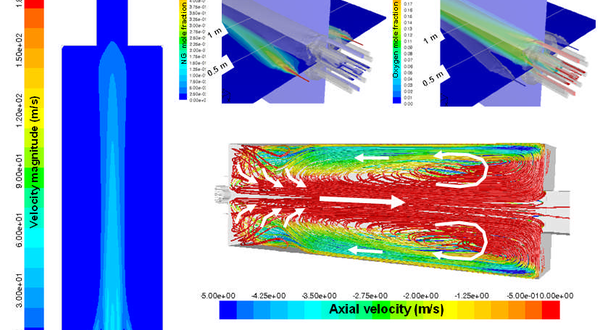

The key highlights from the Future of Furnaces event

The first Future of Furnaces event saw more than 140 industry experts join for two days of online discussions, conference sessions and networking opportunities. Zahra Awan outlines the highlights from the event including: Exclusive coverage, speaker quotes, company insights and more. There was a general consensus from attendees the key to a successful future of furnaces is the community, which must be kept alive.

04 October 2021 -

Fill level Inspection of Molten Aluminium Using AI-Based Machine Vision System

Without a doubt, metals are indispensable to today’s thriving industrial landscape. From automobiles and aerospace to construction and packaging, nearly all the industries rely on metals one way or the other. Given its innumerable use-cases, any compromise to its quality or consistency could lead to serious damage.

29 September 2021 -

AZ China: “Beyond the Horizon” Conference

AZ China provides a summery of what is to be expected at the virtual conference, which will take

place between the 16th to 18th of November 2021. The conference brings industry leaders and many sought-after speakers from China and the world to discuss the future of the industry globally. Also featuring a Q & A with Paul Adkins, where questions on the conference and what will be covered are answered.24 September 2021