Rio Tinto, Geocycle Canada and leading construction materials company Lafarge Canada are working together to reuse waste from the aluminium smelting process to make cement.

In this circular economy initiative, the trio will reduce the need to extract other raw materials and create value from waste.

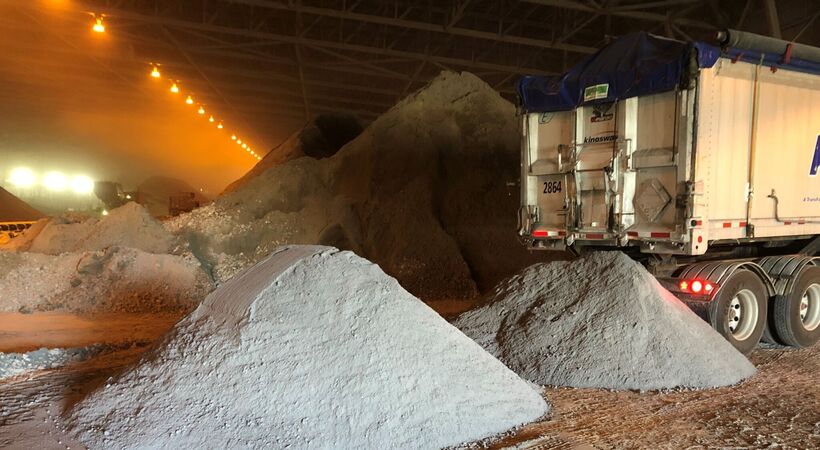

Geocycle Canada, a Lafarge Canada subsidiary, and Rio Tinto have developed a new product called Alextra, made from used potlining, as part of the aluminium electrolysis process that would otherwise go to landfill.

Alextra is the result of years of research and development, aimed at finding new ways to deliver sustainable outcomes and value from used potlining. Lafarge Canada will produce on average one million tonnes of cement a year at its facilities in Bath, Ontario, using Alextra as an alternative to raw materials such as alumina and silica, which are commonly refined or mined for use in the manufacturing of cement.

The companies will explore options to further expand the supply of Alextra from Rio Tinto’s Potlining Treatment Plant in Saguenay-Lac-St Jean to Lafarge Canada's network of cement plants. Rio Tinto Aluminium manager valorization and marketing Stéphane Poirier said: "This partnership shows how Rio

Tinto is innovating to find new ways to reuse waste, generating value from our operations and reducing their environmental footprint. We have worked closely with Lafarge Canada and Geocycle Canada over the past two years to develop a product that meets their needs and look forward to building on this partnership.”

Geocycle Canada senior manager Travis Smith explains: “As a global leader in building materials, we are committed to living up to the responsibility of helping to create a zero waste future. In order to achieve this goal, we need progressive partners such as Rio Tinto, and we look forward to what the future holds as we work to reduce our demand on virgin materials and deliver sustainable products.”